3DPrinting AI Automation AdditiveManufacturing WorkflowOptimization PredictiveMaintenance

In recent years, 3D printing has emerged as a transformative technology with applications across various industries, from aerospace to healthcare. As the demand for additive manufacturing continues to grow, so does the need for streamlining workflows and increasing efficiency in the production process. One of the most promising avenues for achieving this goal is through the integration of artificial intelligence (AI) into 3D printing operations. In this blog, we'll explore how AI-powered automation is revolutionizing the workflow and efficiency of 3D printing.

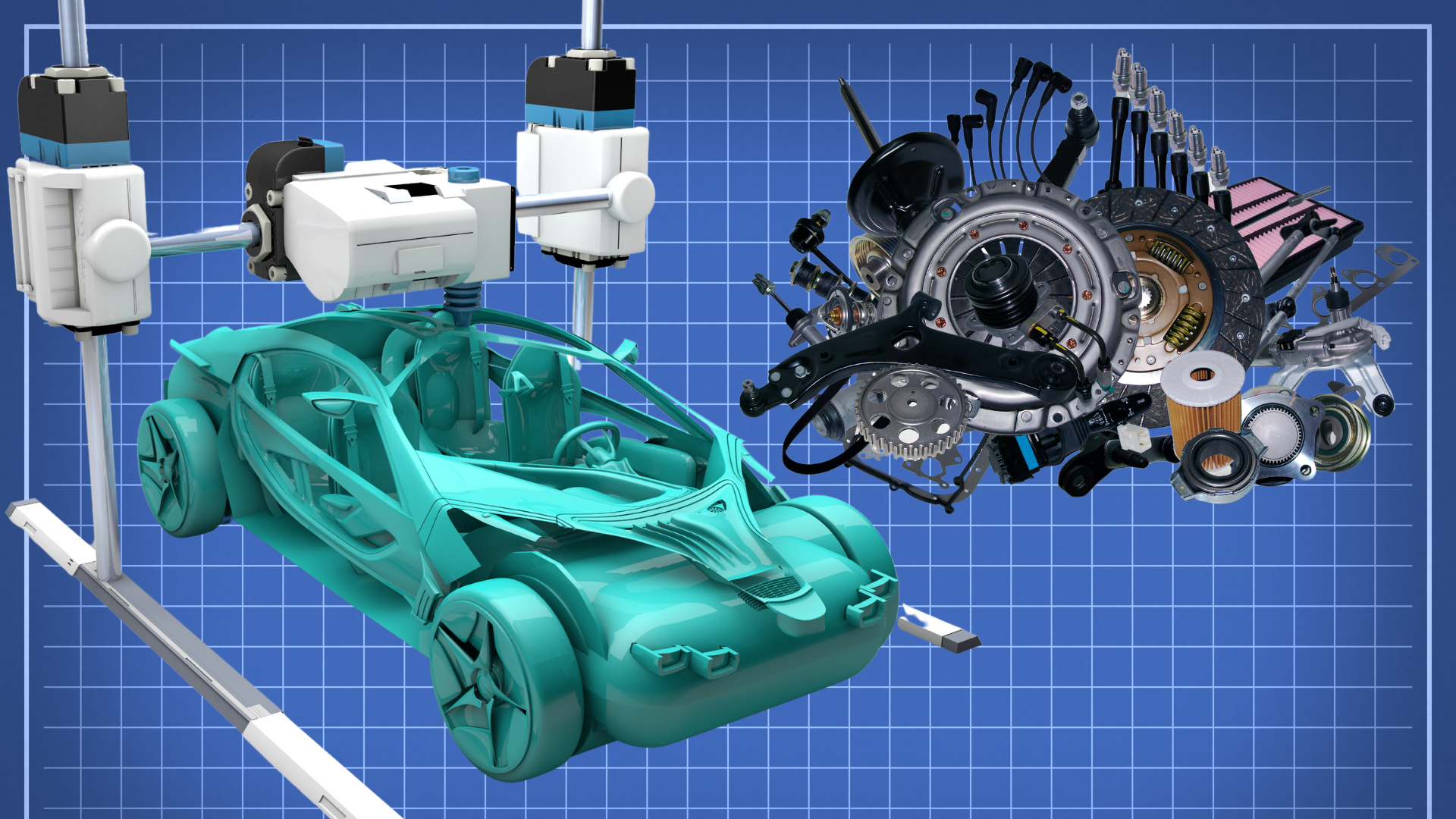

The Role of AI in 3D Printing Workflow: Traditionally, the 3D printing workflow involves several stages, including design, slicing, printing, and post-processing. Each of these stages presents opportunities for optimization through AI-powered automation.

1. Design Optimization: AI algorithms can analyze design requirements and constraints to generate optimized designs automatically. By leveraging generative design techniques, AI can explore a vast design space and identify the most efficient geometries for a given application. This not only reduces the time and effort required for design but also leads to lighter, stronger, and more functional parts.

2. Slicing and Toolpath Generation: Slicing, the process of converting a 3D model into printable layers, is crucial for achieving high-quality prints. AI algorithms can optimize slicing parameters such as layer height, infill density, and support structures to minimize print time and material usage while ensuring structural integrity. Furthermore, AI can generate optimal toolpaths for additive manufacturing processes, maximizing print speed and accuracy.

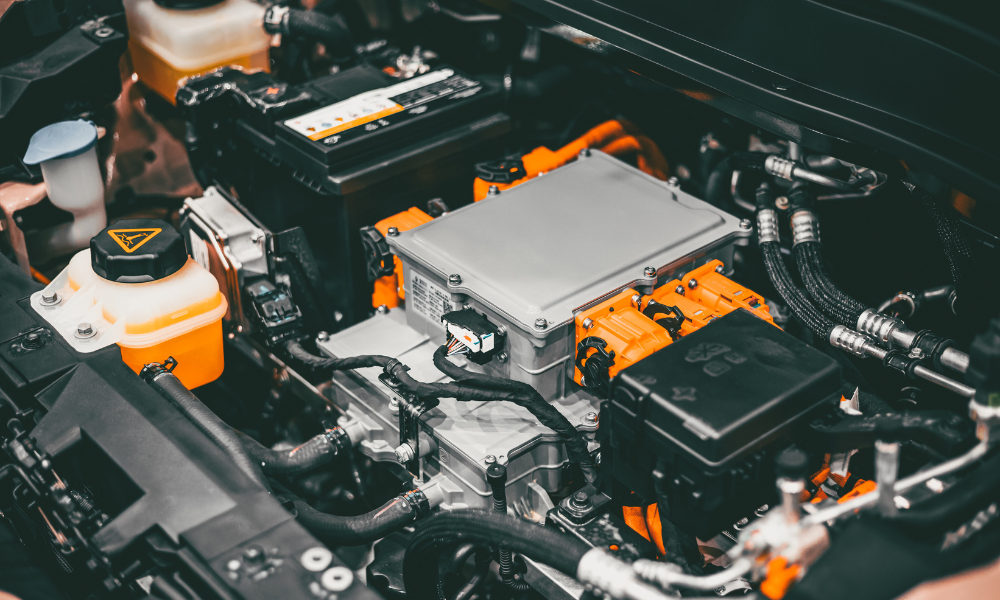

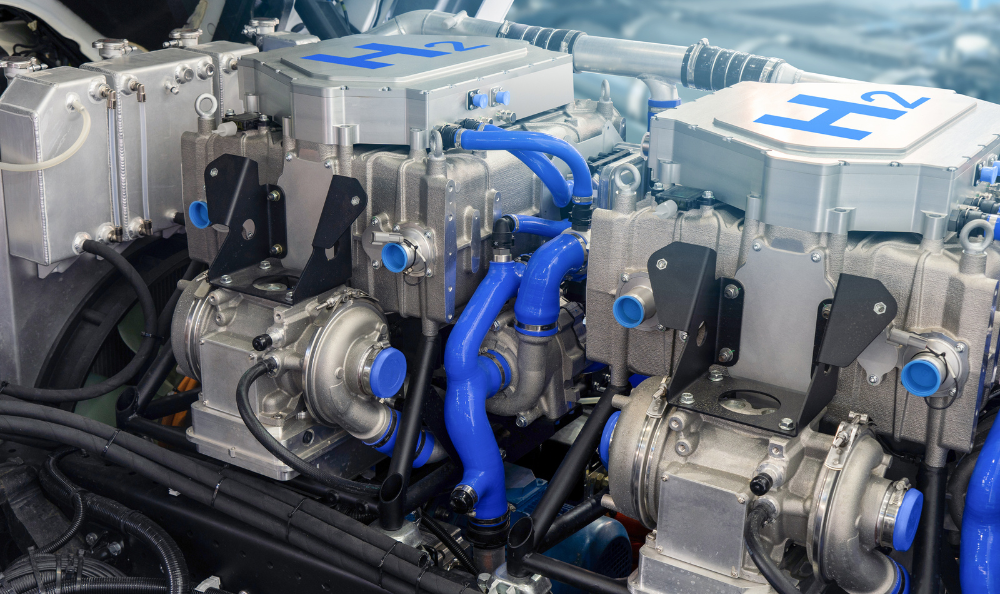

3. Predictive Maintenance: Maintaining 3D printers and associated equipment is essential for minimizing downtime and ensuring consistent print quality. AI-powered predictive maintenance systems can analyze sensor data from printers to detect potential issues before they occur. By predicting component failures and scheduling maintenance proactively, AI helps prevent costly breakdowns and production delays.

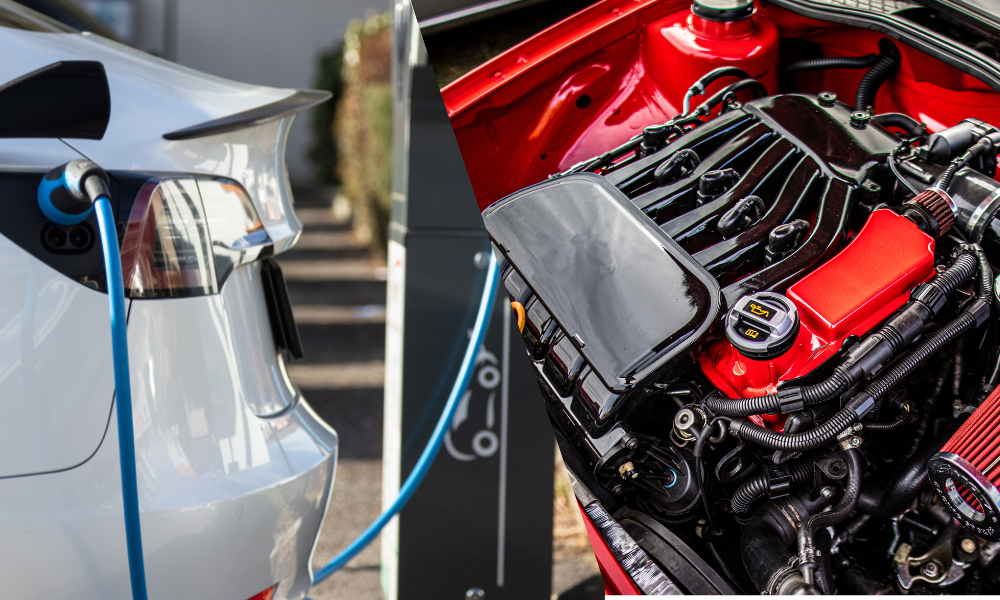

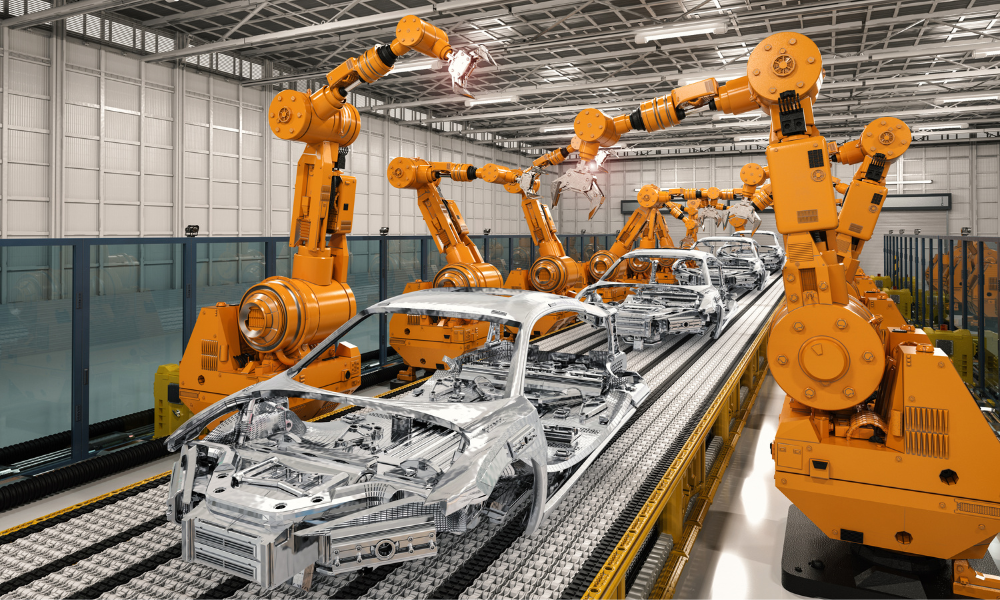

4. Quality Control and Inspection: Ensuring the quality of printed parts is critical, especially in industries such as aerospace and automotive, where safety is paramount. AI algorithms can analyze 3D scans or images of printed parts to detect defects such as warping, delamination, or surface roughness. By automating quality control processes, AI reduces the need for manual inspection and enhances overall print quality.

5. Workflow Optimization: Beyond individual stages, AI can optimize the entire 3D printing workflow by dynamically scheduling jobs, allocating resources, and prioritizing tasks based on real-time data. This level of automation improves overall efficiency, reduces production lead times, and maximizes the utilization of printing facilities.

In conclusion, the integration of AI-powered automation is transforming the landscape of 3D printing by enhancing workflow efficiency across all stages of the production process. From design optimization to quality control and workflow management, AI algorithms are streamlining operations, reducing costs, and enabling new possibilities in additive manufacturing. As the technology continues to evolve, we can expect further innovations that will drive the widespread adoption of 3D printing across industries.

Powered by: Oh! Puhleeez Branding Agency & NowUpskill

3DPrinting AI Automation AdditiveManufacturing WorkflowOptimization PredictiveMaintenance

.png)

.png)